Complete package for measuring and analyzing the frequency response of a system

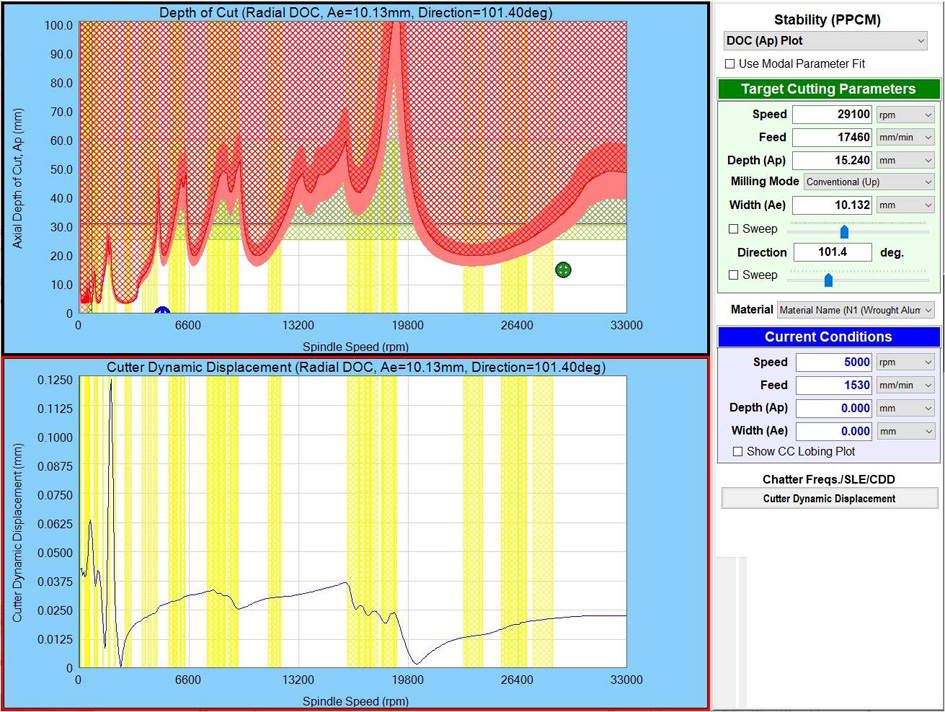

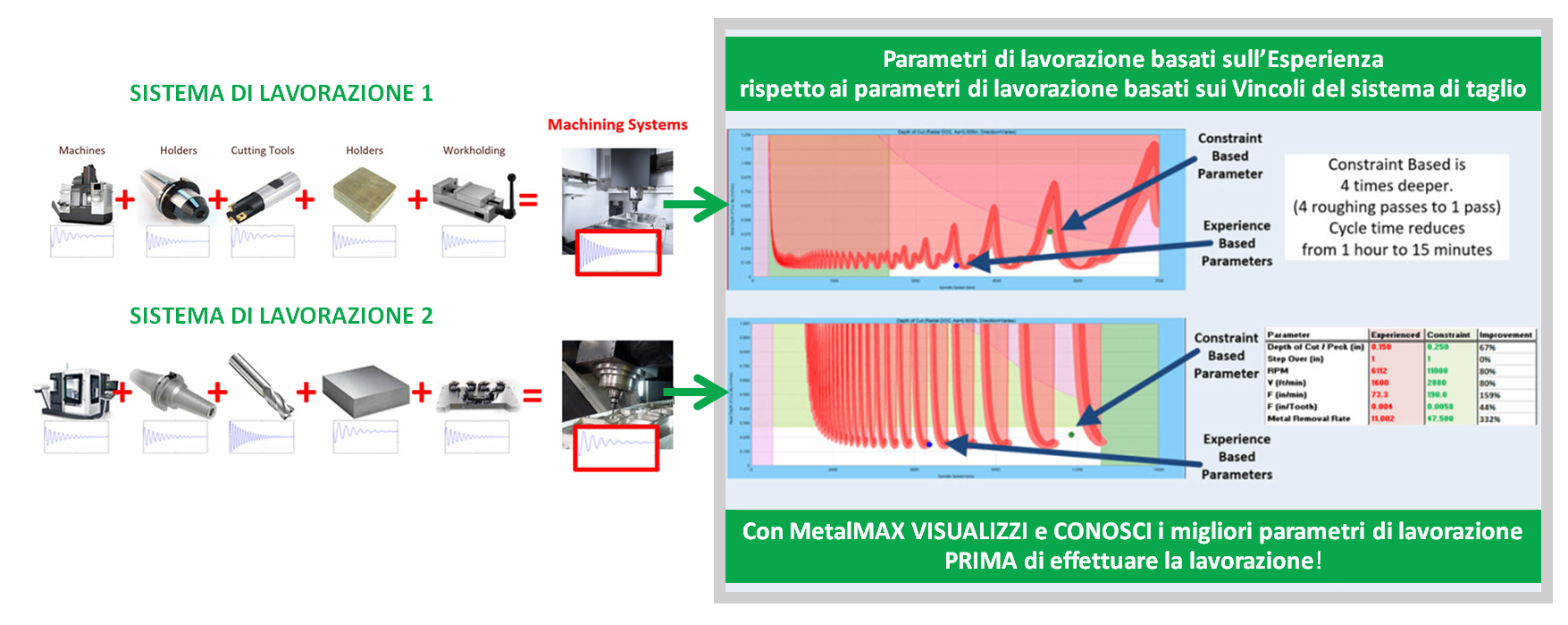

Fully streamlined frequency measurement and analysis package; cutting performance analyzer of tools, components, fixtures, machine-tools and structures; generates process parameter constraint maps (PPCM/Stability Diagrams); calculates modal parameters; qualifies machine dynamics.

- Specialized frequency analyzer package that is tailored for FAST measurement of machine tool dynamics

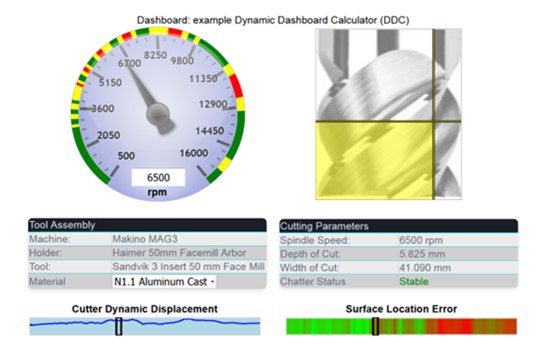

- Cutting performance predictions available DIRECTLY and IMMEDIATELY

- COMPLETE Process Parameters Constraint Maps based on stability analysis

- Combination of workpiece and tool dynamics

- Estimation of surface finish and dimensional accuracy