Tool for Vibration monitoring, analysis, tracking and optimization of cutting process

Vibrations monitoring, analysis and tracking of cutting process with Audio or Vibration sensor; Resonance and chatter detection plus correction. Available for multiple platforms: portable, PC-based, or Machine-Tool NC-fixed.

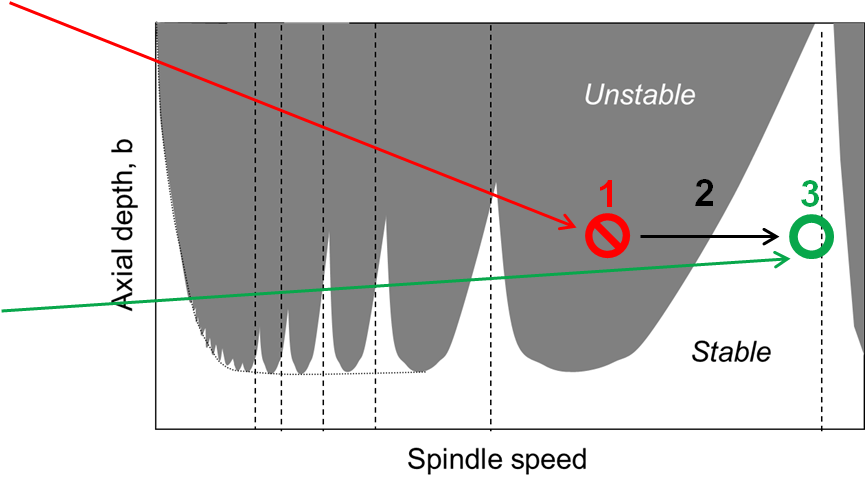

Harmonizer selects the optimum spindle speed range for your process. It utilizes MLI's patented method for detection and avoidance of chatter susceptible spindle speeds based on intelligent spindle speed selection.

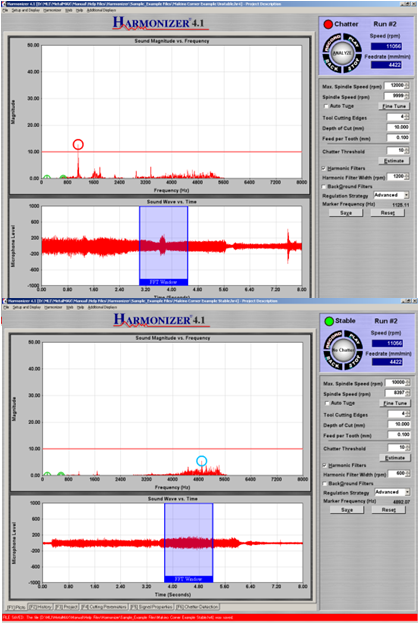

- Record your machining: Harmonizer indicates the presence or absence of chatter in your recorded data

- Analyze: When chatter is detected, Harmonizer automatically selects the optimum spindle speed to avoid chatter

New: Resonant detection and correction capabilities options