Specialized in-process multi-channel vibration data acquisition and analysis package

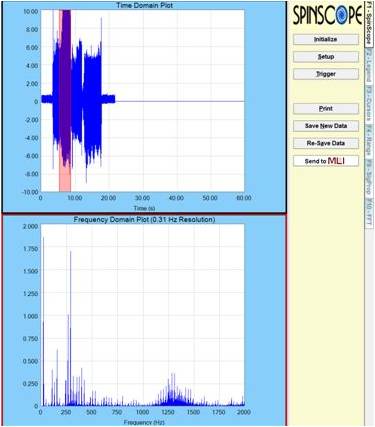

Collects and analyzes multi-channel vibration data acquired during processes using any type of sensor; allows complete monitoring and frequencies analysis on the machine or on the workpiece during machining, including chatter frequencies, resonance frequencies, calculation of velocity, displacements and forces; evaluates spindle dynamic health and efficiency, including bearings frequency analysis, spindle balance and other vibration behavior.

- Full in-process monitoring and analysis using any type of sensor

- Up to four signals collected and analyzed at once (continuous or at specific machining times)

- Complete frequency analysis capabilities

- Additional monitoring functions

- Harmonic filtering and chatter speeds selection functions

- Measurement of displacements

- Specific modules for spindle and machine health dynamic conditions analysis, Balancing, etc.

New: Module for Force monitoring and estimation during machining